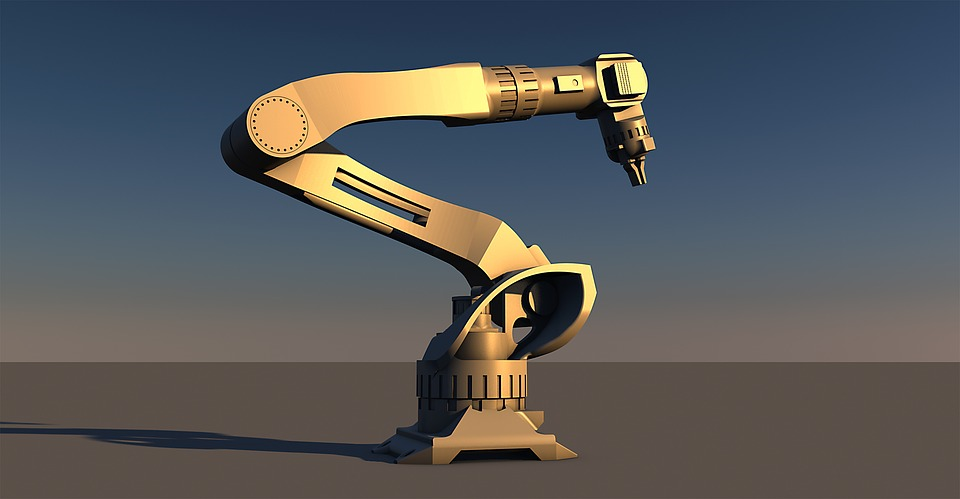

Installing robots and robotic assembly processes in your facility can be a difficult and also overwhelming project. Here is an…

News

THEGEM HANDYMAN / CRAFTSMAN

Branding and quality control are the key to setting your product apart from the rest. Our rotary marking units physically mark…

Edging steel strip for a tube or pipe mill can be critical for your quality and safety needs. Edging is a process…