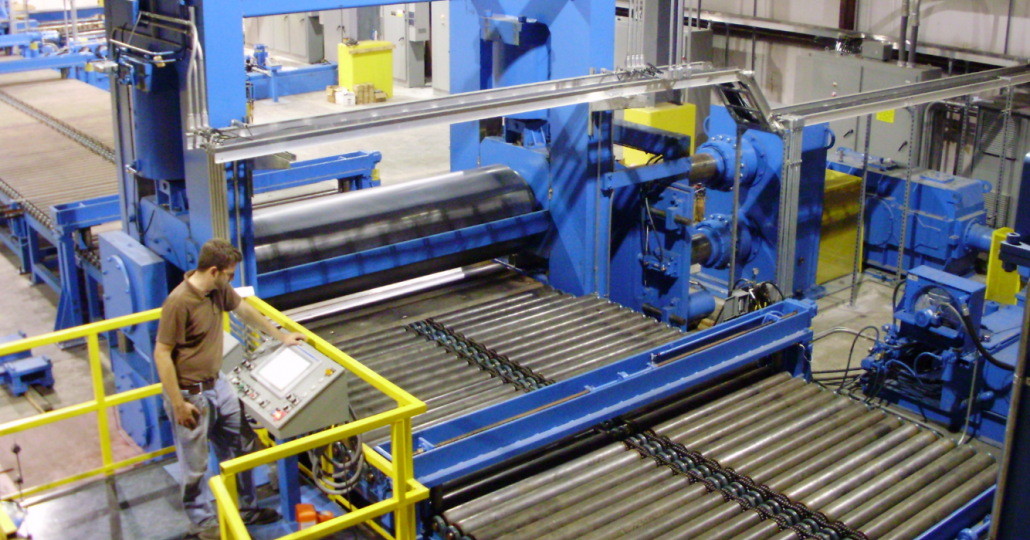

High speed manufacturing, such as stamping, burning, and shearing, depends on flat material in order to increase production and prevent…

News

THEGEM HANDYMAN / CRAFTSMAN

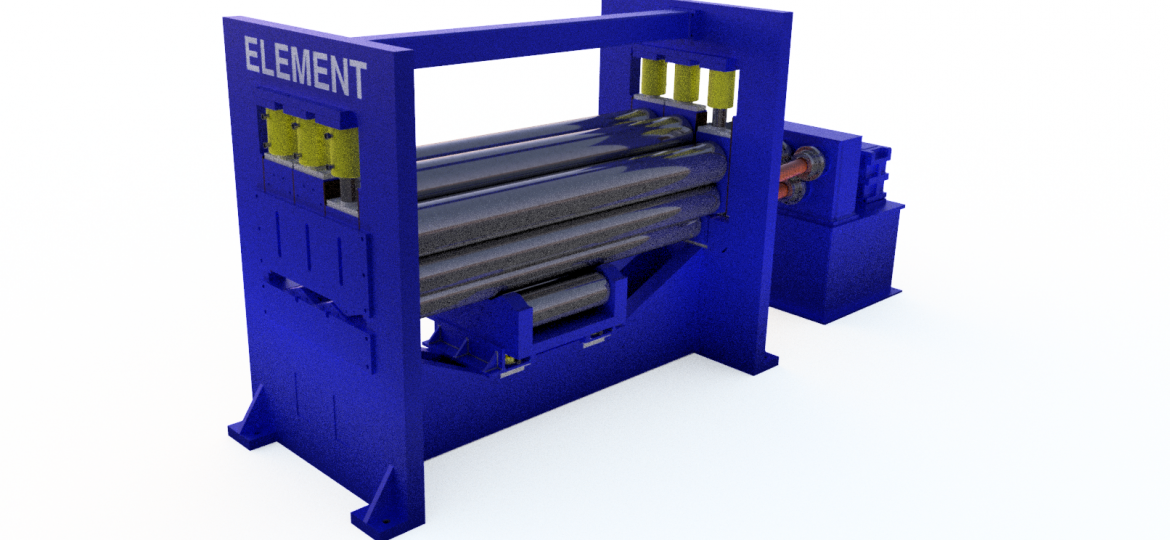

Finding custom rolling mills that meets your requirements can be a frustrating task. Although many used rolling mills are available…