Our metal processing equipment is built to last. Robust designs developed through in depth calculations and proven with years of experience have led to a comprehensive line of processing equipment ready to meet any need.

Our metal processing equipment includes options for repetitive job scheduling, tooling wear tracking and cycle time analysis aids to help you optimize your operations.

Our equipment can provide a high level of accuracy in thickness, length or width of your parts.

WHAT WE OFFER

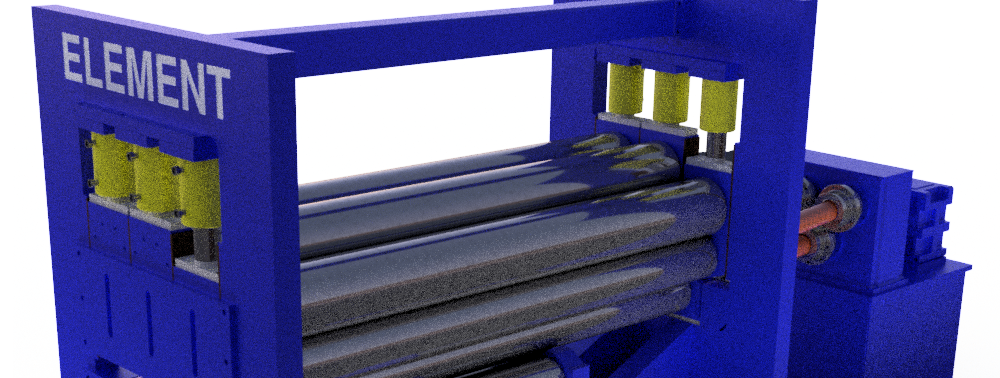

Rolling Mill

Rolling mills are specialized pieces of metal processing equipment used for reducing the thickness of various materials within precise tolerances through a set of rollers.

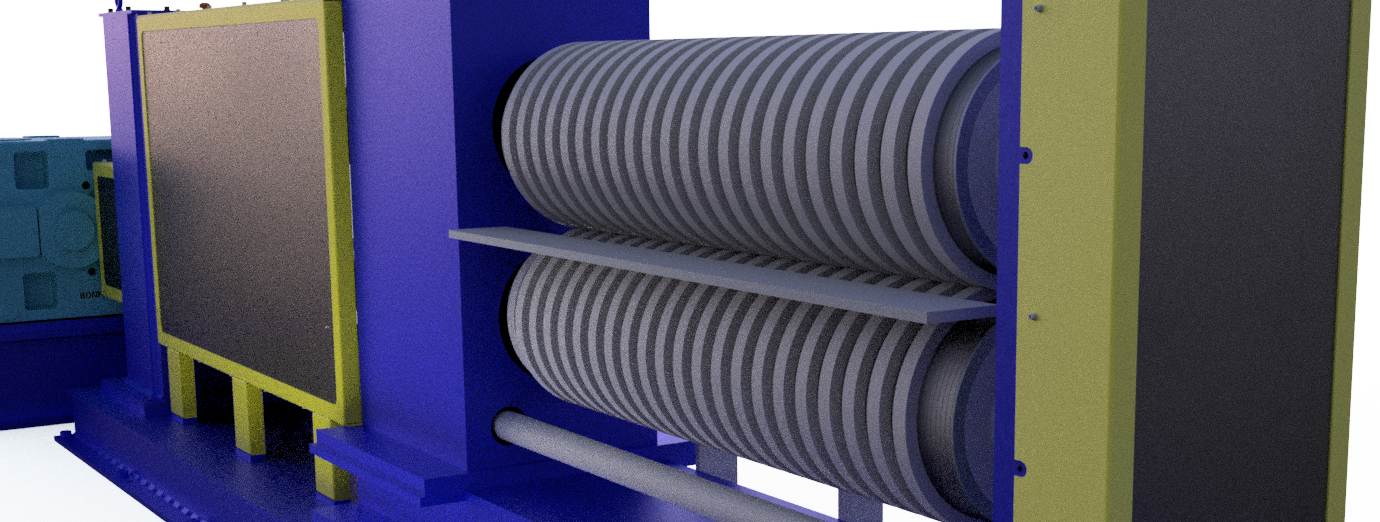

Leveler

Levelers are designed to remove various flatness defects from material. Flatness defects range from observable defects, such as curl and crossbow, to unobservable defects, which do not appear until the processing of material.

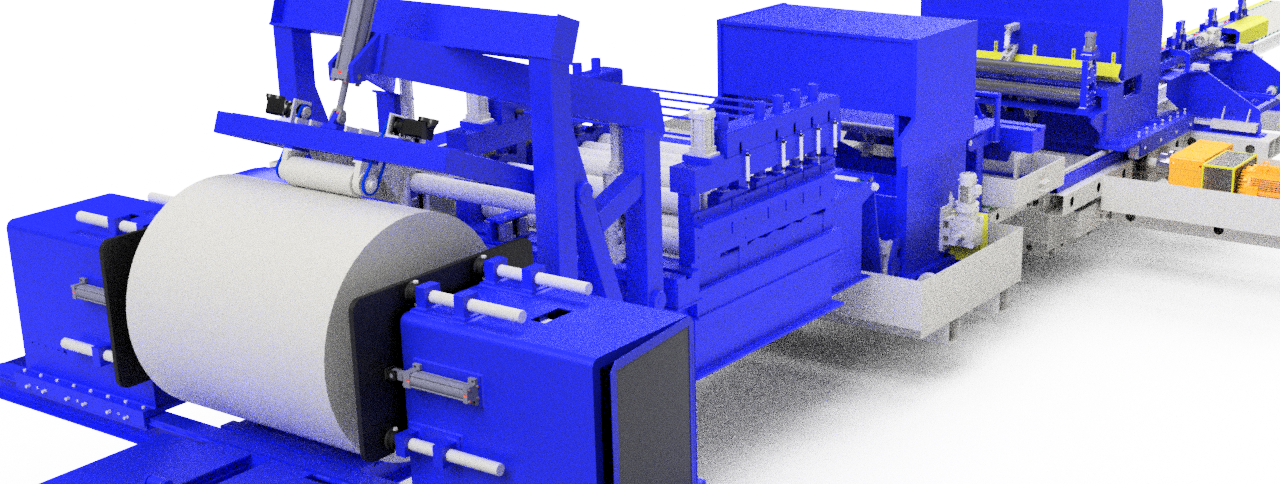

Cut-to-Length Line

Metal cut to length lines are used for processing coiled metals into precise length pieces for resale or further processing. Cut-to-length lines typically incorporate a number of machines to provide value added services while processing coil to piece.

Slitting Line

Slitting lines are used for processing coiled metals into precise width smaller coils or mults for resale or further processing. Slitting lines typically incorporate a number of machines to allow for easy processing of strip.

Edging Line

An edging line is used to condition the edges of material for de-burring, or to induce full round or shaped edges. Edging lines can process individual bars or coil product.

Press Feed

A press feed line is used to feed coiled product to processing machinery such as presses, shears, roll forming equipment or rolling mills. These lines typically consist of incoming coil handling equipment, peeling, and a machine to remove flatness defects from incoming strip.

Remanufactured Equipment

Performing a retrofit on existing equipment can prolong machine lifespan, increase capabilities, and bridge the gap to new markets. With our detailed approach to equipment evaluation and redesign capabilities, we can help improve and upgrade existing machinery.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.