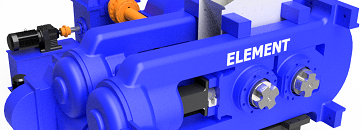

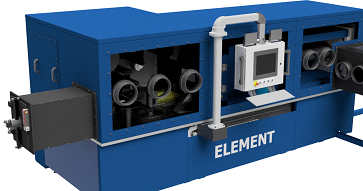

Element specializes in rolling mills designed to reduce lithium metal to very thin gauges for the primary lithium battery market. These rolling mills are designed with very tight tolerances and come in variety of configurations to meet your quality requirements and budget.

Element has experience building and controlling lithium rolling mills to achieve accurate thickness and elongation characteristics, while maintaining good material shape.

Lithium Processing EQUIPMENT

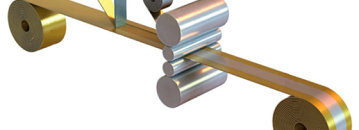

Element also specializes in payoff and winding equipment for processing lithium in coil form. These winding systems utilize highly sensitive tension and strip detection devices to maintain accurate processing and tracking during rolling or extrusion. We also offer a variety of non-contact thickness gauging systems to accurately determine the thickness of material being processed.

Element can also provide custom designed atmospheric enclosures for lithium handling and production. These enclosures are fully customizable with a wide range of atmospheric feedback and closed-loop control options.

LIthium product support services

In addition to supplying machinery for processing lithium materials, product development and support services are available through our close partnership with Lithium Innovations located in South Carolina. Lithium Innovations has a long and proven presence in the lithium processing industry and is the source of a broad range of consultation services to help make your process more efficient and profitable. Aside from consulting services, Lithium Innovations offers a full range of lithium products, including: foils, ingots, anodes, rods, alloys, and specialized lithium products.

Feel free to visit Lithium Innovations’ website by clicking on the logo to learn more about the services and products they can provide.

MINIMUM |

MAXIMUM |

|

|---|---|---|

| Material Thickness | 0.00025″ (0.0063 mm) | 0.25” (6.5 mm) |

| Material Width | 0.500” (12 mm) | 8” (200 mm) |

| Coil Weight | 1 lbs (0.5 kg) | 6 lbs (2 kg) |

| Separating Force | 100 lbs (45 kg) | 50 UST (45 MT |

| Line Speed | 5 FPM (1.5 MPM) | 500 FPM (150 MPM) |

| Thickness Tolerance | +/- 0.0001” (0.0025 mm) | +/- 0.002″ (0.051 mm) |

WHAT WE OFFER

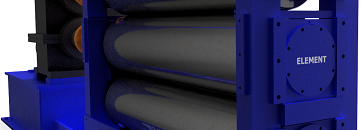

2 High Rolling Mill

Rolling mills consisting of two rolls are known as a 2 High Rolling Mills and are used for anything from temper pass to breakdown of the material.

3 High Rolling Mill

A 3 High Rolling Mill consists of three rolls and is typically used for either performing multiple reduction passes by wrapping material around the center mill roll, or for bonding of dissimilar stacked material passed through the mill. Three High Rolling Mills can also be used for flattening of expanded metal sheets.

4 High Rolling Mill

A four roll configuration is known as a 4 High Rolling Mill, whereby the work rolls are generally smaller in diameter supported by larger backup rollers. These mill can be used for tighter tolerance output material, and for reducing material to extremely small thicknesses.

Compacting Rolling Mill

Compacting rolling mills are used for converting powder or powder like material into continuous strip.

Cladding Rolling Mill

Cladding rolling mills are used to combine two dissimilar materials into a single strip through compression.

Casting Rolling Mill

Casting rolling mills are used for continuous roll casting of strip. Casting rolling mills are typically 2 or 4 high hot mills capable of providing consistent thickness strip from hot cast incoming material.

Embossing Rolling Mill

Specialized rolling mills that emboss a pattern or indent into metal strip are known as embossing mills. These patterns can be used for decoration, to help with structural qualities of tubing or simply to increase material length without significantly decreasing the material thickness for cost savings.

Lithium Metal Processing

We supply a broad range of machinery and services to help in your lithium metal processing application.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.