A leveler removes various flatness defects from material. Flatness defects therefore range from observable defects, such as: edge wave, crossbow, center buckle, quarter buckle; or can be unobservable defects that do not appear until the cutting, burning or processing of material. These defects are due to internal residual stress misalignment inherent in manufacturing. There are three distinct types of leveler machines:

- Plate Levelers

- Corrective Levelers

- Tension Levelers

Each type of leveler listed above accomplishes different leveling tasks.

Levelers are primarily used to remove flatness defects from many different materials. As a result, Element Machinery has built levelers for correction of flatness defects in materials with thicknesses ranging from 0.03125″ (0.8 mm) to 6″ (152.4 mm). The yield strength of the material also determines the overall size of machine necessary. Some typical materials we have had experience with in the past are:

Leveler EXPERIENCE

Levelers remove flatness defects from many different materials. Depending on the material and application requirements, there are many factors to consider when selecting a leveler. These factors could include any of the following:

- Both maximum and minimum gauge material to be processed

- Maximum and minimum material width

- The maximum and minimum yield strength of the material

- Speed or production rate required

- Temperature of incoming material

- Material handling of plate before, during, and after processing

All of the above variables help to finally determine the overall size and capacity of leveler needed. These variables will also help identify

MINIMUM |

MAXIMUM |

|

|---|---|---|

| Material Thickness | 0.063″ (1.588 mm) | 6″ (152.4 mm) |

| Material Width | 1″ (25.4 mm) | 144″ (3,658 mm) |

| Coil Weight | 500 lbs (228 kg) | 100,000 lbs (45,359 kg) |

| Separating Force | 50 UST (45 MT) | 6,000 UST (5,443 MT) |

| Line Speed | 50 FPM (15 MPM) | 200 FPM (61 MPM) |

Our Levelers have met a wide variety of requirements across multiple applications. As a result, they have also been established in many different industries and have been supplied with many options, such as:

CONTROL OPTIONS |

PLATE MATERIAL |

INDUSTRIES SERVED |

|---|---|---|

|

|

|

TOLERANCES |

MATERIALS |

|---|---|

| Levelers remove defects from material, and also raise the classification of material to an industry standard. These standards support downstream processing of the material and ensure consistent quality. These industry standards identify tolerances on flattened product, and include: | Some advanced features Element has likewise supplied in the past include:

|

WHAT WE OFFER

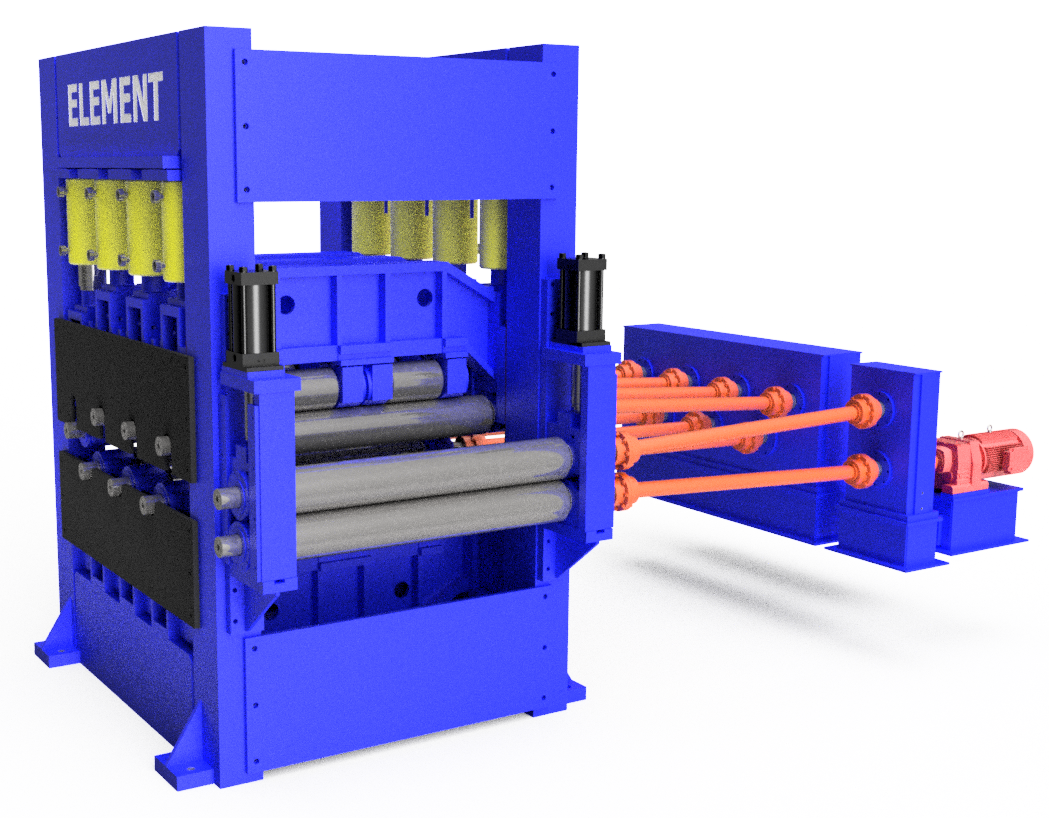

PLATE LEVELER

Plate levelers flatten both thin and heavy gauge materials. They typically have individual roll adjustment with closed loop control (position/force), therefore allowing for generating machine setting recipes to make operator’s jobs easier. Furthermore, each roll may be driven through a distribution box or individual drives.

CORRECTIVE LEVELER

Corrective levelers straighten thinner materials and have bank-type adjustment of work rolls. They are also equipped with multiple flights of backup rolls. In order to correct minor strip shape defects, roll bending is similarly made possible by adjusting the backup flights.

TENSION LEVELER

Tension levelers level material by stretching it into plastic deformation. In order to achieve the high amounts of tension necessary, a tension leveler utilizes bridle rolls to isolate tension for leveling. The bridle roll design also allows for controlling tension at upstream and downstream coilers.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.