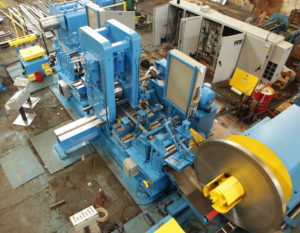

A continuous edging machine is used to condition the edge of material strip for downstream processing. These machines typically consist of multiple sets of profiled hardened alloy steel rollers that induce a certain shape of the material. These can be

- Individually adjustable

- Bank adjustable

- Vertically adjustable

Continuous EDGING Equipment Options

With Element’s Edging lines, we offer several options to increase the productivity of your equipment. These options can extend the edging roll life, decrease feed up and tail out time or offer quick changeovers to new parts. Some standard options are:

- Multiple profile edging rolls.

- Exotic alloy edging rolls for prolonged wear life.

- Coil handling equipment.

Element edging lines offer feedback and control of roll positioning that provides the ability to establish standard part recipes on specific product offerings.

Continuous EDGING Experience

Element has supplied edging lines to feed into tube mills and other similar equipment to provide clean edges for welding or forming. We have also supplied edger’s with tooling specially designed to reduce roller change out time or pattern swapping for efficient productivity.

Tolerances:

Our edging lines have met the following tolerance standards:

- ASTM (American Society for Testing)

- ANSI (American National Standards Institute)

- AISI (American Iron and Steel Institute)

- EN (European Standards)

- JIS (Japanese Industrial Standards Committee)

Listed below are some of the general specifications for Element Edging lines:

MINIMUM |

MAXIMUM |

|

|---|---|---|

| Material Thickness | 0.063″ (1.588 mm) | 0.50″ (12.7 mm) |

| Material Width | 1″ (25.4 mm) | 72″ (1,828 mm) |

| Coil Weight | 500 lbs (228 kg) | 100,000 lbs (45,359 kg) |

| Line Speed | 50 FPM (15 MPM) | 200 FPM (61 MPM) |

| Number of Stands | Single | 4 Adjustable Edging Stands |

Our edging lines have met a wide variety of requirements in many applications. As a result, they’ve been established in many industries and have developed a broad range of options. Here is a list of options and controls that we can supply with our systems:

CONTROL OPTIONS |

PLATE MATERIAL |

INDUSTRIES SERVED |

|---|---|---|

|

|

|

Experience |

MATERIALS |

|---|---|

Element Machinery has provided:

|

Edging lines are capable of processing the following materials:

|

WHAT WE OFFER

SINGLE BAR EDGING

Single bar edging is used to condition the edges of individual parts and pieces. These machines may consist of multiple sets of profiled hardened alloy steel rollers that consequently induce a desired shape on the side of material.

CONTINUOUS EDGING

A continuous edging machine is used to condition the edge of material strip for downstream processing. These machines therefore consist of multiple sets of profiled hardened alloy steel rollers that induce a desired shape of the material.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.