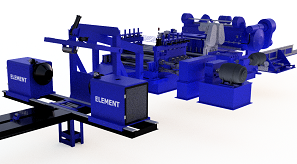

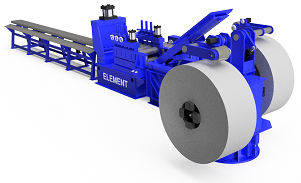

The heavy gauge cut to length line is designed for material thicknesses larger than 1/2″ (12.7 mm). By alternating between corrective leveling and plate flatteners, a wide range of input thicknesses can be accommodated. Heavy gauge lines utilize large scale mechanical or hydraulic shears for cutting material, also known as Stop-Go CTL. With heavy duty stacking sections allow for handling bundles of cut plates. Due to the increase of thickness of the material, a more robust peeling and material handling section is used. Heavy gauge line are also useful for the processing of exotic alloys with higher shear strength ratings.

Heavy Gauge Cut-to-Length Line Options

With any Element Cut to Length line, we offer several options that are available to increase the productivity of your equipment. Some of the options that we offer to maximize the capacity of our lines include:

- Coil handling equipment

- Regenerative braking for establishing strip tension

- Heavy gauge flatteners

- Edge control to maintain consistent strip position

Element lines use high resolution feedback devices to provide tight cut tolerances across any length of piece. Our most accurate cut to length lines can reach up to 1/8 ASTM standard cut lengths.

Heavy Gauge Cut-to-Length Line Experience

Element has supplied heavy gauge cut to length lines for up to 1″ x 120″ (25.4 x 3048 mm) mild steel strip. As an industry leader in heavy gauge processing lines, Element equipment is supplied with power and safety factors to allow for the demanding stresses of processing thick material.

Tolerances:

Our Cut-to-Length line has met the following tolerance standards:

- ASTM (American Society for Testing)

- ANSI (American National Standards Institute)

- AISI (American Iron and Steel Institute)

- EN (European Standards)

- JIS (Japanese Industrial Standards Committee)

Element Machinery has pioneered cross light/heavy gauge cut-to-length lines. Our experience has included material as defined by the following dimension ranges:

MINIMUM |

MAXIMUM |

|

|---|---|---|

| Material Thickness | 0.005″ (0.127 mm) | 1″ (25.4 mm) |

| Material Width | 1″ (25.4 mm) | 144″ (3,658 mm) |

| Coil Weight | 500 lbs (228 kg) | 100,000 lbs (45,359 kg) |

| Cut Length | 1″ (25.4 mm) | 80′ (24 m) |

| Line Speed | 50 FPM (15 MPM) | 200 FPM (61 MPM) |

| Cut Tolerance | +/- 0.010″ (.254 mm) | +/- 1″ (25.4 mm) |

Our Cut-to-Length lines have met a wide variety of multiple applications. They have been used in different industries with the following options

CONTROL OPTIONS |

PLATE MATERIAL |

INDUSTRIES SERVED |

|---|---|---|

|

|

|

WHAT WE OFFER

LOOPING CUT-TO-LENGTH LINE

Looping cut-to-length lines are designed so that the material is accumulated in a loop while the shear performs a cut to allow for cutting material without stopping the feed.

FLYING SHEAR CUT-TO-LENGTH LINE

Flying shear cut-to-length lines allow for the shear to accelerate and synchronize to strip speed to cut material without stopping material feed.

HEAVY GAUGE CUT-TO-LENGTH LINE

Heavy gauge cut-to-length lines are designed for material thicknesses larger than 1/2′′ (12.7 mm). By alternating between corrective leveling and plate flatteners, a wide range of input thicknesses can be accommodated.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.