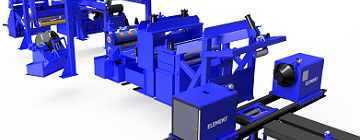

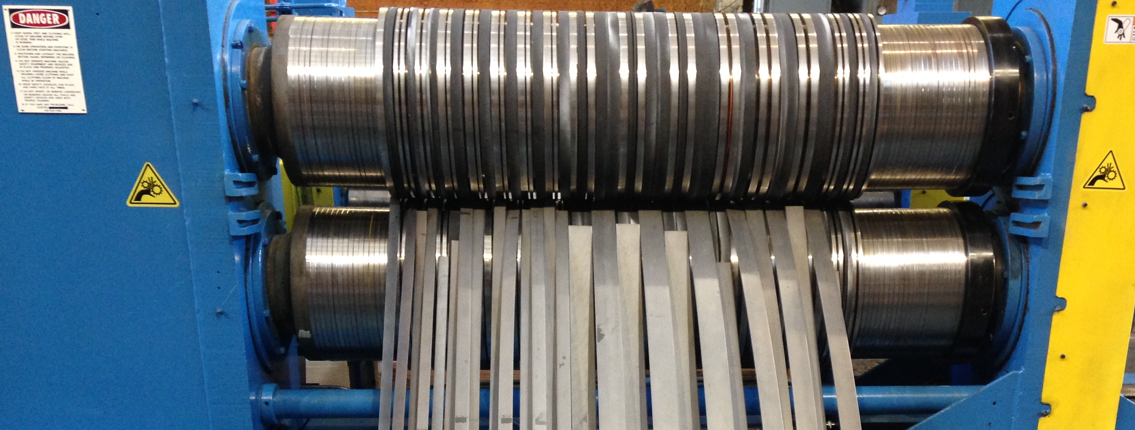

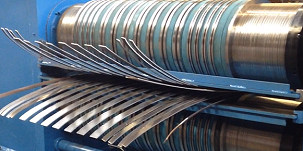

A drive assisted slitter is designed so that the slitter motor is used to help push material through the downstream process. In this setup the speed of the shear knife is synchronized to the material strip speed. With this method it is best used for heavy gauge slitting and slitting of materials with low shear stress ratings.

Drive Assisted Slitter Equipment Options

With any Element Slitting line, we offer several options that are available to increase the productivity of your equipment. Some of the options that we offer to maximize the capacity of our slitting lines include:

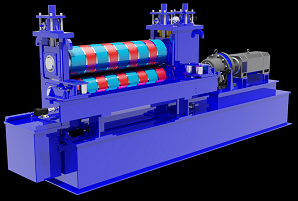

- Removable slitting heads.

- Turret style slitting arbors.

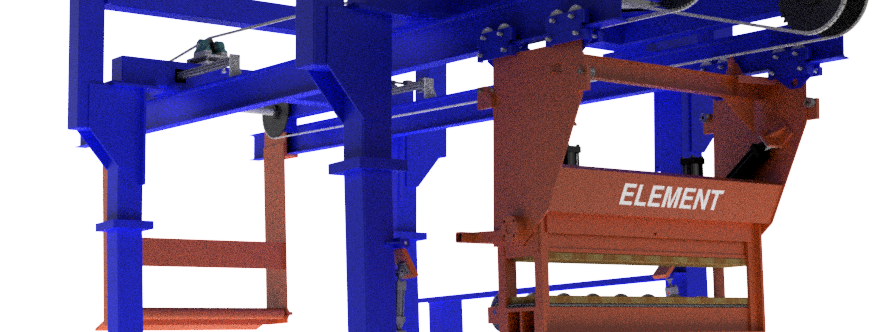

- Scrap handling systems (Cutters, choppers, bailers, or scrap winders).

Drive Assisted Slitter ExperiEnce

Element has provided slitters with variable material penetration and a wide variety of incoming material shear stress ratings.

Element Machinery has supplied slitting lines to handle 0.005″ (0.13 mm) to 0.0625″ (15.9 mm) strip widths from:

MINIMUM |

MAXIMUM |

|

|---|---|---|

| Material Thickness | 0.005″ (0.127 mm) | 0.50″ (12.7 mm) |

| Material Width | 1″ (25.4 mm) | 72″ (1,828 mm) |

| Coil Weight | 500 lbs (228 kg) | 100,000 lbs (45,359 kg) |

| Line Speed | 50 FPM (15 MPM) | 500 FPM (152 MPM) |

| Number of Cuts | 2 Cuts (Edge Trimming) | 30 Cuts |

Our Slitting lines have met a wide variety of multiple applications they have also been used in different industries as well as have been built with the following options.

CONTROL OPTIONS |

PLATE MATERIAL |

INDUSTRIES SERVED |

|---|---|---|

|

|

|

TOLERANCES |

MATERIALS |

|---|---|

| Slitting lines typically have relatively tight tolerances on overall piece widths. As with most metals processing, the industry standards that govern these tolerances are: | Some advanced features Element has supplied in the past include:

|

WHAT WE OFFER

LOOPING SLITTING LINE

A looping slitter is the most common slitter for slitting of light gauge materials and narrow widths (also known as mults).

PULL THRU SLITTING LINE

A pull through slitting line is used by decoupling or allowing the slitter motor to free spin and slitting material by pulling it through the knives with the recoiler drive.

DRIVE ASSISTED SLITTING LINE

A drive assisted slitting line is designed so that the slitter drive is used to help push material through the downstream process.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.