EXPERIENCE

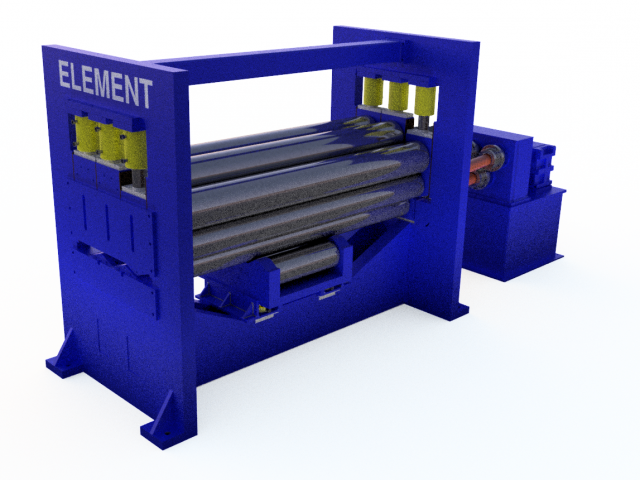

Our metal processing equipment is built to last. Robust designs developed through in depth calculations and proven with years of experience have led to a comprehensive line of processing equipment ready to meet any need.

Element’s assembly stations utilize generic code that allows for on the fly adjustment of assembly steps. With configurable work instructions at the machine level, operators have a clear visual guide for each step of an assembly process minimizing necessary training.

Our experience in high speed automation equipment has led us to generate solutions for the paper, glass, metal processing, automotive and medical industries. Our focus on minimizing cycle times ensures our equipment exceeds customer cycle time requirements and removes production limitations.

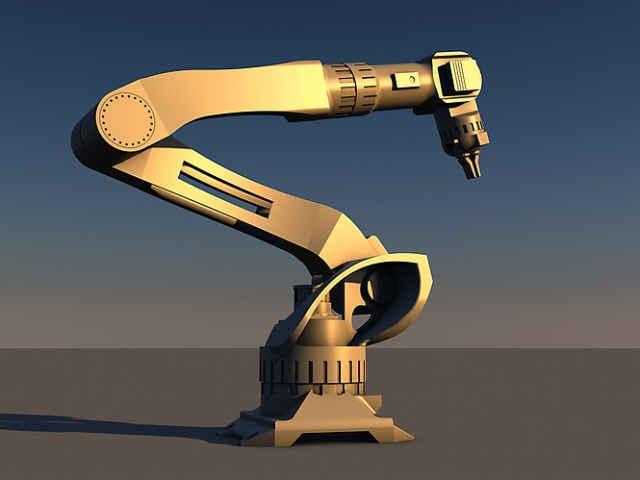

Industrial robotic systems offer a new benchmark in flexibility, safety, reliability, quality and throughput. Element Machinery specializes in tailoring robotic automation solutions to fit your process needs.

Our packaging equipment can be used to integrate with our metal processing, high speed automation, robot cells or third party equipment to give you a fully automated process.

Food and pharmaceutical equipment is challenging to find due to high demand for quality and reliability, while operating in harsh environments. Element specializes in supplying systems that perform and last in these difficult applications.

Element tracks projects by breaking them down into reasonable phases or milestones. This ensures consistency in tracking and reporting across projects and provides regular benchmarks to our customers during the flow of a project.

Have a unique problem that requires a unique solution? Element can help. With our broad experience base, Element can assist with any engineering challenges you might be facing. We have experience translating testing, production, process improvement and overhaul challenges into fully functioning solutions tailored to you.

Utilizing our knowledge of 3D design software, we can model and evaluate any part to highlight potential issues, identify common wear part redesign possibilities to improve machine uptime and perform overall machine limit tests.

Automating a process can provide a practical, robust and long term solution to changing business needs while relieving safety concerns and improving product consistency. Our experience in a wide range of automation products can help you achieve your automation goals.

Adding new functions to existing equipment can be an effective way to increase flexibility of equipment or realize process improvements.

Trying to determine if old equipment can run new products can be tough. We utilize our knowledge of equipment, automation, modeling, statistical analysis and onsite inspections to give our customers qualified reports detailing potential issues and immediate maintenance needs.

Performing a retrofit on existing equipment can prolong their lifespan, increase capabilities and bridge the gap to new markets. With our detailed approach to equipment evaluation and redesign capabilities, we are well suited to help you through this process.

Element’s service engineers have years of experience providing our customers with periodic inspections or assistance during downtime events. We provide the highest level of service rooted in years of equipment building and startup experience.

Element provides the best metal processing equipment and assistance. International heavy equipment specialists. Contact us for your industrial engineering needs.