High speed manufacturing, such as stamping, burning, and shearing, depends on flat material in order to increase production and prevent damage to machinery. Consequently, many manufacturers have very strict quality requirements that they pass on to their vendors.

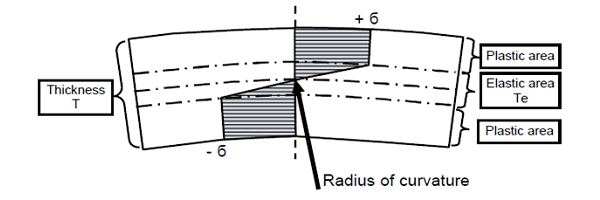

Flattening material is all about the difference between “elastic” and “plastic” deformation. Material in elastic deformation will spring back to its original shape, whereas plastic deformation means the material is permanently bent. A leveling machine’s goal is therefore to plastically bend material and bring it back to a perfectly flat shape.

A custom levelers ability to straighten material is based on the machine’s roll configuration. Specifically, the leveler’s work roll bends material over its radius, which therefore allows the machine to flatten material – as shown in the image below:

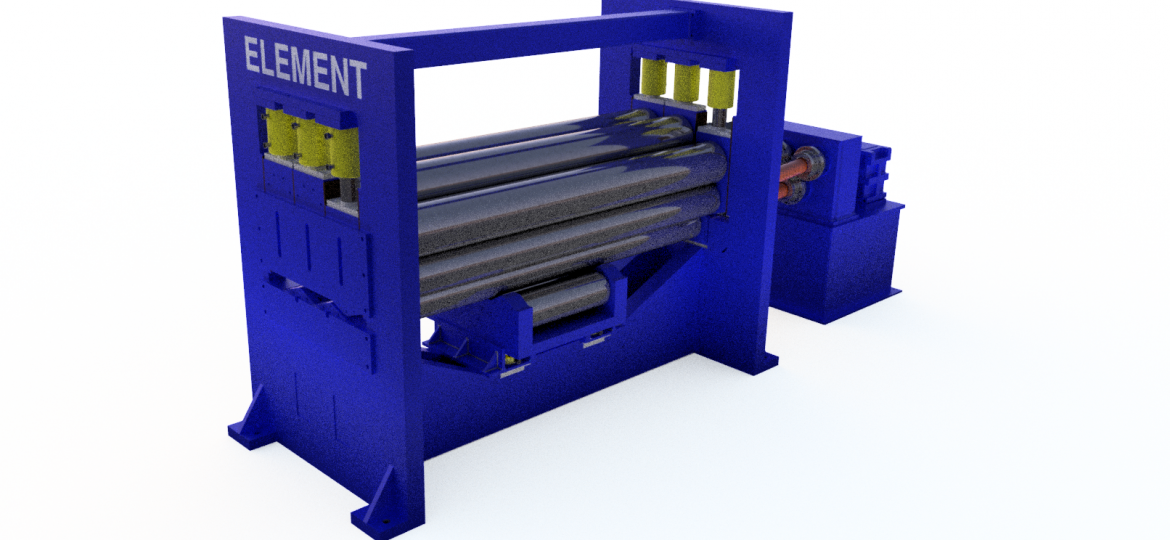

The leveler’s roll diameter, roll centers and depth of roll penetration chiefly determine the capacity of the machine. Depending on the material thickness, width and yield strength to be processed, there are several standard types of levelers that can help. Element can supply any of the following types of levelers to meet your requirements:

Call us today with your leveling needs and we can help find a solution that fits your needs, and your budget. With over 40 years of experience in flattening of metal products, we’re happy to help.

Visit our Leveler page to learn more about machines we offer for flattening of metal products. Let’s build something!