Tension levelers are typically used for leveling material by stretching the material into the elastic region. In order to achieve the high amounts of tension necessary, a tension leveler can utilize bridle roll sets that incrementally increase the tension into the main leveling zone and incrementally decrease the tension to the downstream process or recoiled. These bridle rolls are typically individually driven by regenerative motor systems that provide the necessary resistance to build tension. The main leveling zone can contain either a corrective leveler or temper mill to further remove flatness defects. Tension leveling typically provides the optimum correction of shape defects in metal strip but is limited in the ability to level thicker strip.

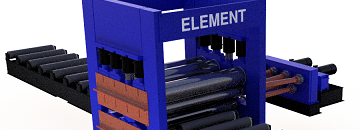

Tension Leveler Equipment options

With any Element Levelers, we offer several options that are available to increase the productivity of your equipment. Some of the options that we offer to maximize the capacity of our levelers include:

- Stacking sections are available to stack leveled plates into bundles for shipment.

- Variable roll geometry options are available to provide additional bending capabilities.

- Closed loop positioning control allows for generating machine setting recipes for common plate runs.

Tension Leveler Experience

Element has supplied tension levelers for:

- Steel

- Copper

- Brass materials

- Aluminum

A Leveler can be used to remove flatness defects from many different materials. Element Machinery has built levelers for correction of flatness defects in materials. The yield strength of the material also determines the overall size of machine necessary.

CONTROL OPTIONS |

PLATE MATERIAL |

INDUSTRIES SERVED |

|---|---|---|

|

|

|

TOLERANCES |

MATERIALS |

|---|---|

| Levelers remove defects from material, and also raise the classification of material to an industry standard. These standards support downstream processing of the material and ensure consistent quality. These industry standards identify tolerances on flattened product, and include: | Some advanced features Element has supplied in the past include:

|

WHAT WE OFFER

PLATE LEVELER

Plate levelers flatten both thin and heavy gauge materials. They typically have individual roll adjustment with closed loop control (position/force), therefore allowing for generating machine setting recipes to make operator’s jobs easier. Furthermore, each roll may be driven through a distribution box or individual drives.

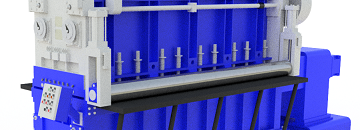

CORRECTIVE LEVELER

Corrective levelers straighten thinner materials and have bank-type adjustment of work rolls. They are also equipped with multiple flights of backup rolls. In order to correct minor strip shape defects, roll bending is similarly made possible by adjusting the backup flights.

TENSION LEVELER

Tension levelers level material by stretching it into plastic deformation. In order to achieve the high amounts of tension necessary, a tension leveler utilizes bridle rolls to isolate tension for leveling. The bridle roll design also allows for controlling tension at upstream and downstream coilers.

HOW CAN WE HELP YOU?

Give us a call (855) 447-7648 or send us a message here.