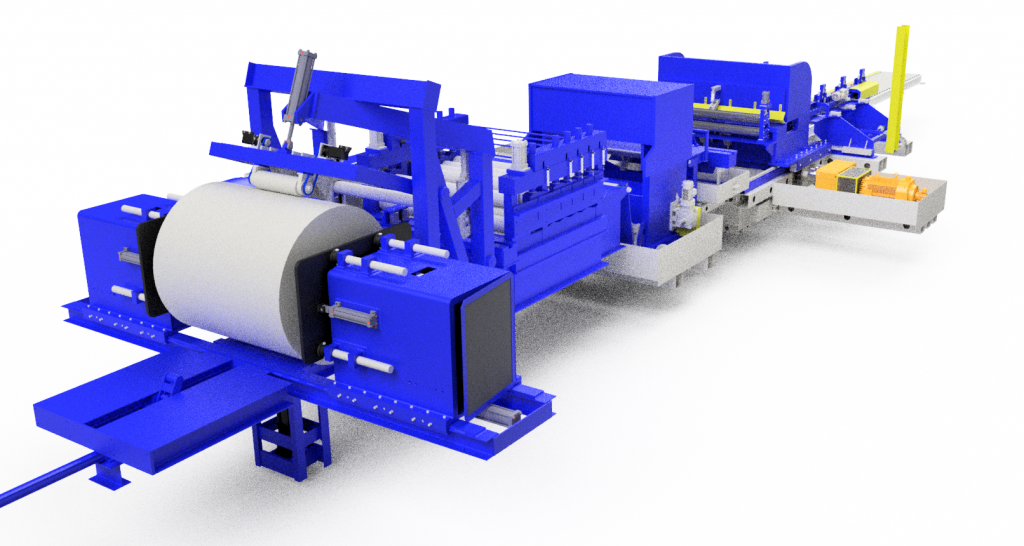

High speed manufacturing, such as stamping, burning, and shearing, depends on flat material in order to increase production and prevent…

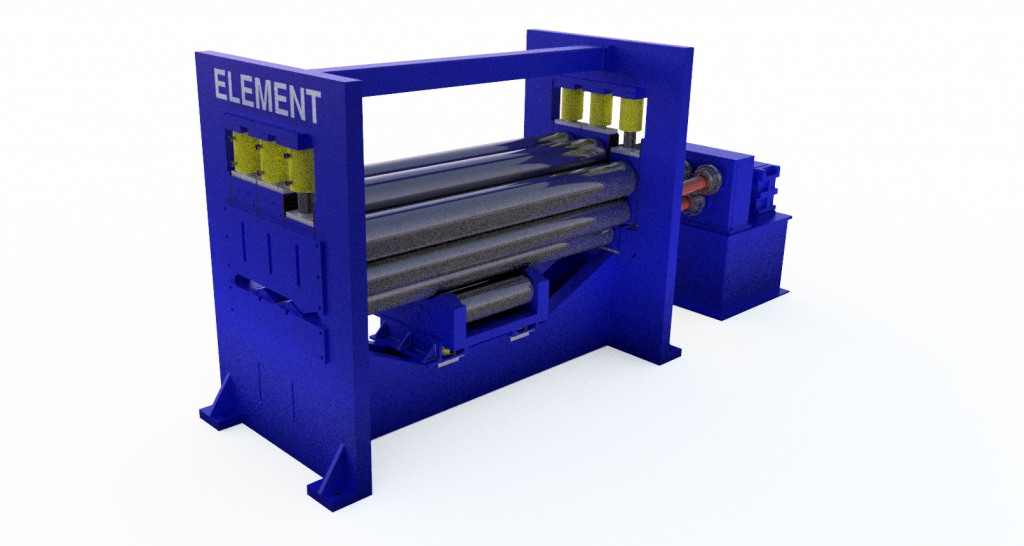

Finding custom rolling mills that meets your requirements can be a frustrating task. Although many used rolling mills are available…

Installing robots and robotic assembly processes in your facility can be a difficult and also overwhelming project. Here is an…

Branding and quality control are the key to setting your product apart from the rest. Our rotary marking units physically mark…

Edging steel strip for a tube or pipe mill can be critical for your quality and safety needs. Edging is a process…

Making the decision to purchase machinery and control upgrades to improve your manufacturing process can be tough to justify. Fortunately, the…

This article gives some great insight into the benefits of a control retrofit on your machine or line: Control Engineering…

This article is good advice for those looking to expand their business with custom automation: Control Engineering – Deciding to…

Here is an excellent article on steel leveling: The Fabricator – Roller Leveling 101 Element Machinery has a number of tools…

A great article highlighting cut-to-length line designs and technologies: The Fabricator – Cutting Edge of Cut-to-Length Lines Cut-to-length lines can…