Edging steel strip for a tube or pipe mill can be critical for your quality and safety needs. Edging is a process that uses an edger (or edge conditioner) to chamfer (or fillet) sharp edges of material before going into a forming line. Upstream slitting and shearing operations form these sharp edges, and they can cause many different quality issues in your process. By edging the material, you may encounter some of the following benefits:

- Produce higher quality welds in tube or pipe due to removal of burred corners, and

- Allow for safer handling of roll form line due, due to removal of sharp edges

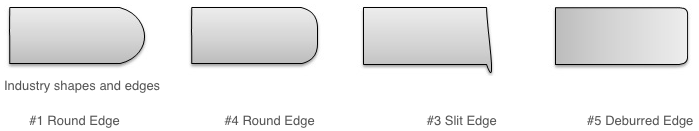

Steel strip come in a variety of different edges that can be difficult to identify, so here are a few standard industrial shapes for reference:

Our edger unit shown above is an awesome example of one of our latest designs for continuous edging. The low profile design allows for incrementally forming a shape on incoming strip to make welding and forming more consistent.

Element Machinery’s edger units can be supplied in both driven or idle configurations, and can be easily installed in an existing line. Call us today and we can help you focus on building a better and safer manufacturing process.

For more information about edge solutions, please visit our edging products page. Let’s build something!